How to Choose the Right Deep Groove Ball Bearing for Your Application

Deep groove ball bearings are among the most common types of rolling-element bearings used in a vast range of machinery and equipment. Their simple design, high durability, and versatility make them suitable for everything from electric motors and household appliances to heavy-duty industrial machinery. However, selecting the right deep groove ball bearing for your application isn’t as straightforward as picking a size off a chart.

Choosing the correct bearing requires careful consideration of several factors such as load type, speed, operating conditions, lubrication, and more. Making the right choice can dramatically improve machine efficiency, reduce maintenance costs, and extend operational lifespan. This article provides a comprehensive guide to help you select the right deep groove ball bearing for your specific application.

What Is a Deep Groove Ball Bearing?

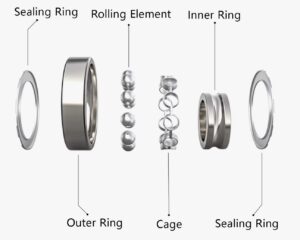

Deep groove ball bearings consist of an inner ring, an outer ring, a cage, and a set of steel balls. Their name comes from the deep raceway grooves in which the balls rotate. This design allows them to support both radial and axial (thrust) loads and makes them particularly efficient for high-speed rotation.

They come in single-row and double-row configurations and may include additional features such as seals, shields, or snap rings.

Step 1: Understand the Load Requirements

One of the first and most important considerations when selecting a bearing is the type and magnitude of load it will encounter.

Radial Load: Acts perpendicular to the shaft and is the primary load supported by deep groove ball bearings.

Axial Load: Acts parallel to the shaft. Standard deep groove ball bearings can handle moderate axial loads but may need to be reinforced or replaced with a specialized type for high axial loads.

Combined Load: Many real-world applications involve a mix of radial and axial loads. Ensure the bearing is rated for the combined load it will experience.

Understanding your load conditions is crucial because overloading a bearing leads to premature failure, increased heat, and noise.

Step 2: Determine the Speed Requirements

Deep groove ball bearings are ideal for high-speed applications, but each bearing has a specific speed limit based on its size, internal design, lubrication, and other factors.

Limiting Speed: This is the maximum speed a bearing can operate without overheating or failing. Check the manufacturer’s catalog for this data.

Application Speed: Calculate the operational speed of your application and ensure it is well within the bearing’s limit.

Lubrication Impact: Oil lubrication typically allows for higher speeds than grease, but grease is more convenient for sealed-for-life designs.

Always choose a bearing that can comfortably exceed the speed demands of your application to ensure smooth and safe operation.

Step 3: Consider Precision and Tolerance Requirements

In high-performance applications such as robotics, CNC machinery, or aerospace components, bearing precision is critical.

Tolerance Classes: Bearings are manufactured in tolerance classes (e.g., ABEC, ISO P). Higher numbers (like ABEC 7) indicate tighter tolerances and greater precision.

Runout and Noise: Applications requiring minimal vibration or noise, such as medical equipment or electric motors, should use high-precision bearings.

For general machinery, standard tolerance bearings usually suffice. For precision-critical applications, consult with the bearing supplier for optimal class selection.

Step 4: Evaluate Environmental and Operating Conditions

Bearings operate in a wide variety of environments, and factors like temperature, contamination, and moisture can affect performance and longevity.

Temperature: Standard bearings typically operate up to 120°C (248°F). For higher temperatures, look for heat-stabilized variants.

Contamination: Dust, dirt, and other contaminants can quickly damage a bearing. Sealed or shielded bearings are recommended for such environments.

Corrosion: If your application is exposed to water or corrosive chemicals (e.g., in marine or food processing environments), choose stainless steel or coated bearings.

Selecting a bearing material and design that suits the environment can significantly extend its service life.

Step 5: Choose the Right Bearing Type and Features

Standard deep groove ball bearings come in various designs, and selecting the appropriate configuration can enhance performance.

Single-Row Bearings: The most common type. Ideal for general-purpose ap

Double-Row Bearings: Offer higher load capacity but may have lower speed ratings. Suitable for compact designs where a single row isn’t sufficient.

Sealed vs. Shielded:

Sealed Bearings (with rubber seals) offer better protection and are often pre-lubricated.

Shielded Bearings (with metal shields) protect against larger particles and allow for higher speed.

Snap Rings: Some bearings come with snap ring grooves for easy axial location.

Pick features based on ease of installation, required protection, and operational longevity.

Step 6: Select the Right Lubrication

Lubrication plays a pivotal role in bearing performance. It reduces friction, prevents wear, and helps manage heat.

Grease-Lubricated Bearings: Common in sealed-for-life applications; easier to maintain.

Oil-Lubricated Bearings: Used in high-speed or high-temperature conditions; requires regular maintenance.

Specialty Lubricants: Available for food-grade, high-vacuum, or low-temperature environments.

Ensure the lubricant is compatible with your application and re-lubrication intervals are achievable with your maintenance schedule

Step 7: Calculate Bearing Life

Bearing life is typically estimated using the L10 life—the number of revolutions at which 90% of identical bearings will still be operational.

The life is affected by:

Load (both radial and axial)

Speed

Lubrication

Mounting accuracy

Environmental factors

Use manufacturer-provided calculators or bearing selection software to estimate life based on your specific conditions. Opt for bearings with a safety margin if your application is mission-critical.

Step 8: Work with Reputable Suppliers

Choosing a reliable supplier is as important as selecting the bearing itself. A good supplier can:

Help interpret technical data

Recommend suitable products

Provide quality certifications and traceability

Offer engineering support for unusual applications

Stick with trusted manufacturers ,avoid counterfeit products that can fail unpredictably.

Conclusion

Choosing the right deep groove ball bearing requires more than just knowing the size and speed of the shaft. You also need to consider load conditions, environmental challenges, speed, precision and lubrication needs. By carefully evaluating these factors, you can ensure optimal bearing performance, reduce downtime and extend the life of your machine.

If you are unsure or are dealing with a special application, feel free to consult an application engineer or use the manufacturer’s software tools. With the right guidance and the right selection process, deep groove ball bearings can provide excellent reliability and efficiency for years to come.

Need help with bearing selection?

Feel free to contact us with the details of your application – we will be happy to provide guidance, or contact engineering support for more complex needs.